blown film machine parts name

ISHAN Multilayer Blown Film Extrusion Machine. We adapt our modular lines to your requirements and thus help you to get the best out of your production.

Extrusion An Overview Sciencedirect Topics

PP TQ Blown Film Machine.

. Check all Gear Box. Domino Inkjet Printer Model A420I SN AST000104604 100-240 Volts 4 Amps. Blowing Machine Spare Parts bravan2 2020-12-16T0235510000.

5 Layer Blown Film Co-ex Line Highly versatile die design leading to optimum quality of Barrier as well as Facilitates optimisation of Tie Layer Blown Film Co-extrusion Lines In Technical collaboration with. Blown Film Machine Exporter generally has a better balance of mechanical properties than cast or extruded films because it is drawn in both the transverse and machine directions. Replace the oil of the Gear box of reel.

Contact Us Get More Spare Parts. Due to the lack of brand name and visibility its sales network was limited exporting mainly to Europe. At Reifenhäuser Blown Film we develop and manufacture modular 1- to 12-layer blown film lines from 300 mm to 6500 mm wide.

PVC Heat Shrink Film Machine. No matter mono layer multi-layer or other blown film machines we are able to develop and produce according clients specific. What are the components of the film blowing machine.

WINDSOR MACHINES LIMITED Formerly DGP Windsor India Ltd 5403 Phase IV GIDC Vatva Ahmedabad. D-73773 Aichwald phone 49 1577 5329827. Multilayer Blown Film Machine.

ABA Blown Film Machine With Oscillation Haul Off Monolayer Blown Film Plant Standard Model Wide Width Film Machine. Process of Blown Film Extrusion. The first step is to melt the polymer in an extruder.

We thus cover the entire technology spectrum - for the production of blown films for standard packaging sophisticated technical films for food packaging with barrier properties and agricultural films with a film. The blown-film process involves extruding a relatively thick tube which is then expanded or blown by internal air pressure to produce a relatively thin film. HA Blown Film Extruder Final Product.

75150kghr depends on extruder size. HDPE LDPE LLDPE Plastic Film Application Flexible packaging bags T-shirt bag garbage bag shopping bag Material used HDPE LDPE LLDPE virgin raw material recycled material CaCO3 compound biodegradable material masterbatch and additives Output range. A Variety of Blown Film Extrusion Machines and Parts Offered by POLYSTAR.

Polymer resin often in the form of beads is loaded into a hopper and fed into a heated barrel with a screw. The screw and material barrel may be made from a nitrogen-treated chromium-molybdenum-aluminum alloy. Plastic extrusion machine manufacturing since 2004.

Fill out my online form. Open Motor and check the Main Bearing Electrical terminal and other. The tube can be collapsed to form double-layer layflat film or can be slit to make one or two single-layer film webs.

They are designed for highest quality resource efficiency and profitability and set new technological standards. The name EVO stands for blown film lines of the latest generation which have one thing in common. Spare Parts For Blow Molding Machine MotorPumpLampValveAir CylinderPLC Tempurature Controller XTG-7000.

Extruder screw 70 mm ld 24 die diameter 250 mm and 300 mm gap 09 mm and 12 mm corona treatment wrapper 1600 mm working width. Auch Folien Technik e. Cost-saving efficient high output plastic recycling machine PP HDPE LDPE LLDPE blown film machines pellet machines and flexo printing machines sold over 30 countries in plastic machinery industry with solid reputation.

The traction motor of this unit adopts. Carry bags Shopping bags Water Pouches Garbage Bags Shrink Wrap Film Oil. Filter Default Name A-Z Name Z-A Size Small-Large Size Large-Small.

Blown Film Extrusion Equipment. Open the catalog to page 10. Special make MOQ 50pcs.

Matila is one of leading brands in manufacturing film extrusion blowing machines with almost 30 years experience. For any flexible films such as. Check the Machine safety system Check and Refill Gear Oil Gear Box Check Electrical Equipment pp film blowing machine.

The blown film machine is an economical solution to create films for plastics bags. 2 12 Blown Film Die. Check all Moving parts pp film blowing machine.

The screw is used to transport the polymer down the. Advantages of Blown Film Machine Exporter -. The traction auxiliary machine is composed of main comp The traction auxiliary machine is composed of main components such as traction frame herringbone plate traction roller take-up mechanism and traction motor.

Film Layflat width Range. ABA Blown Film Machine. 30 Lakh Get Latest Price.

Mechanical properties of the thin film include tensile and flexural strength and toughness. Check all Heater Line. Polyethylene PE Low Density Polyethylene LDPE.

The situation has however changed radically since 2010 when POLYSTAR converted itself into a brand that manufactures blown film extrusion lines. PE Emboss Stretch Film Making Machine. The main motor may have frequency control of motor speed to improve speed regulation and save electricity.

Double Die Blown Film Machine. Blown Film Machine Film Plastic Blown Film Machine 1000mm ABA T-shirt Bag Plastic Blown Film Extruder Hdpe Blown Film Machine 3000000-3200000 Set 10 Sets Min. We have a full list of blown film extruders.

Blown film extrusion can be complex so we will now explain each step of the process in detail. Plastic film winders are available from Plastic Machinery Parts new and used good quality equipment available for production of flexible plastics that can be used in the converting industry for blown film a Plastic Film Winding Machine can be used for sheet cast foam and bag making Products. Mono-blown film lin in good working condition for processing LD and LLD-PE film width max.

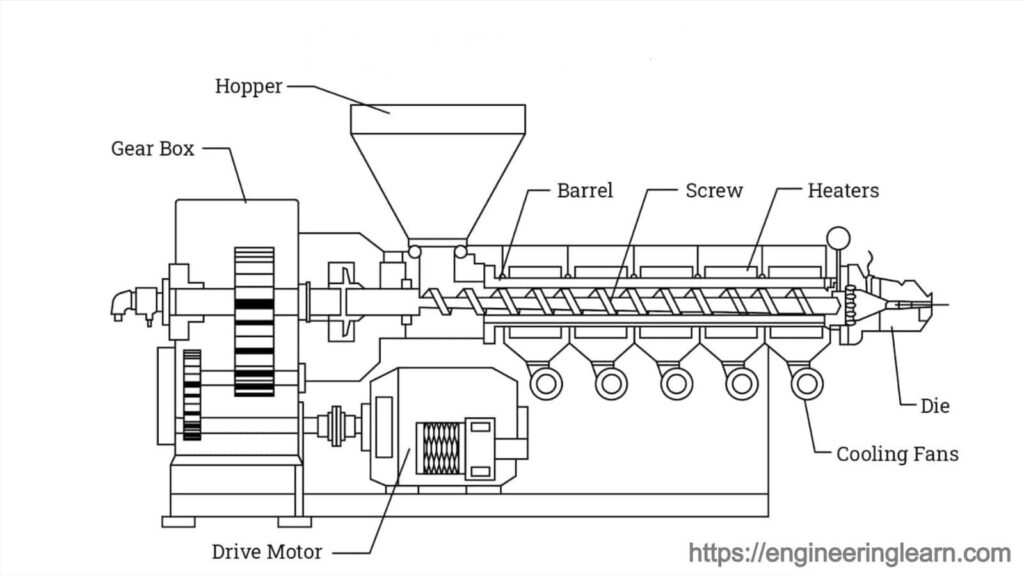

Screw and barrel motor inverter heaters die head winder and tower.

Blown Film Bandera Plastics Extrusion Italy

Extruders An Overview Sciencedirect Topics

Direct Extrusion An Overview Sciencedirect Topics

Hydraulic Press Machine Parts Types Working Applications With Pdf

Molding Machine Preventive Maintenance

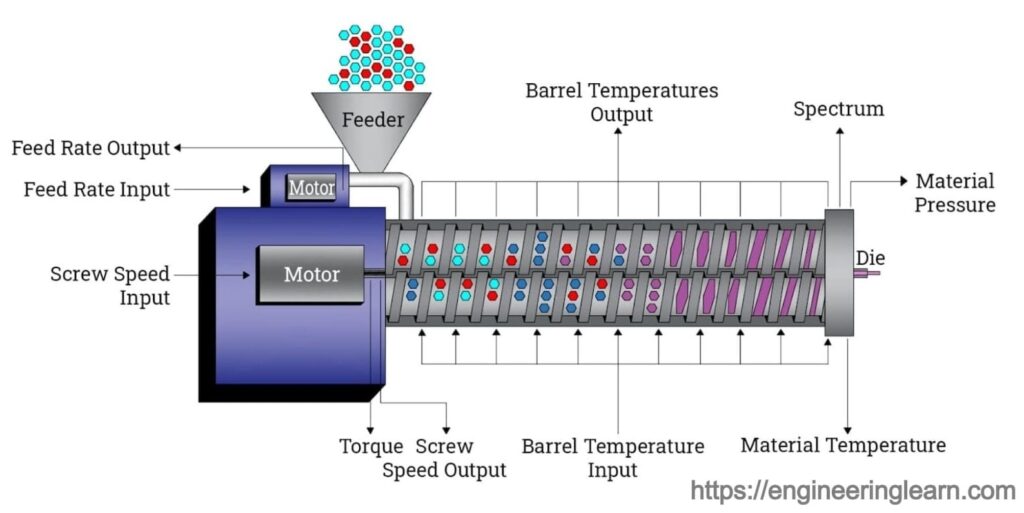

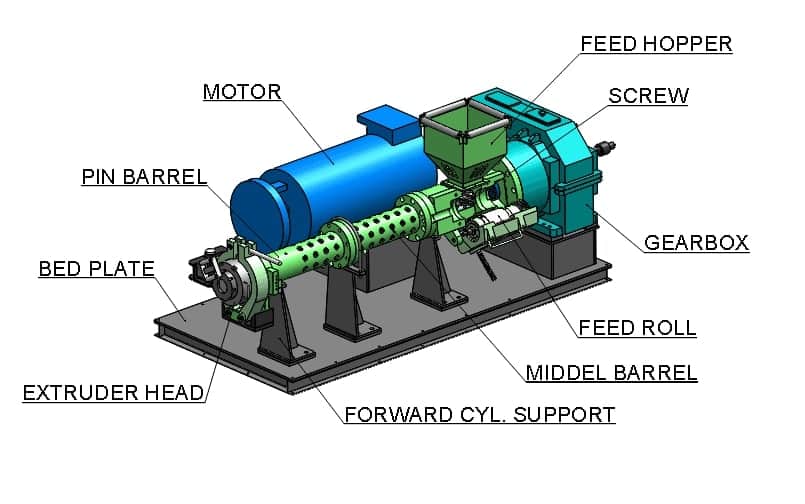

Types Of Extruders Application Working Principle Engineering Learn

Extrusion Design Dies Tooling Aec

Types Of Extruders Application Working Principle Engineering Learn

Injection Molding Machine Construction Working Application Advantages And Disadvantages

Blown Film An Overview Sciencedirect Topics

Cast Film Extrusion An Overview Sciencedirect Topics

Tutorial Injection Molded Parts

Types Of Extruders Application Working Principle Engineering Learn